State-of-the-Art Equipment for High-Quality Environmental Services

Ensuring the environmental health and safety of projects that include commercial, industrial, residential developments, retail and government construction, renovation, demolition, assessment and remediation – is a complex undertaking.

Our work takes place in settings where a wide range of environmental threats can pose a risk to human health and safety. In addition to decades of experience, training, specialized expertise and certifications, our team members have the advantage of state-of-the-art equipment for detecting, measuring, and mitigating environmental risk quickly and accurately.

Here’s an overview of some of the technology we use to ensure the highest quality results for the rapid identification and resolution of environmental issues:

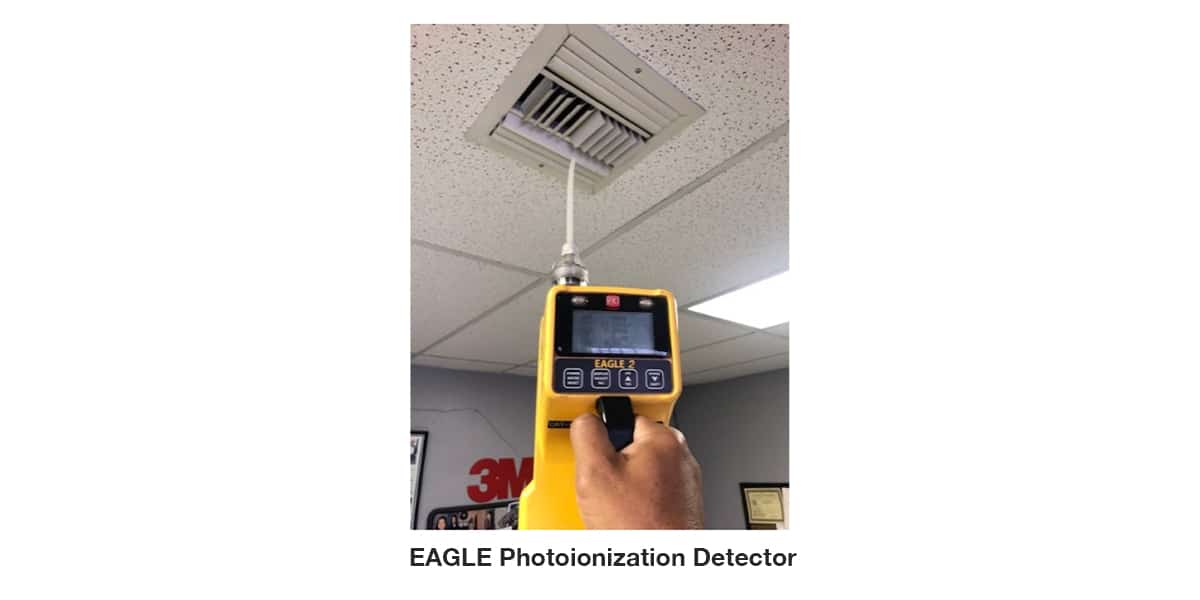

EAGLE Photoionization Detector

The photoionization detector (PID) monitors and detects a variety of volatile organic compounds (VOCs), hydrocarbons, and other potentially harmful gases in the air. Used as a screening tool to detect contamination in soil, underground tanks, clarifiers, or other sources of harmful emissions, this powerful equipment detects high or low levels of hydrocarbons and VOCs from a distance of up to 125 feet, allowing for rapid response and remediation.

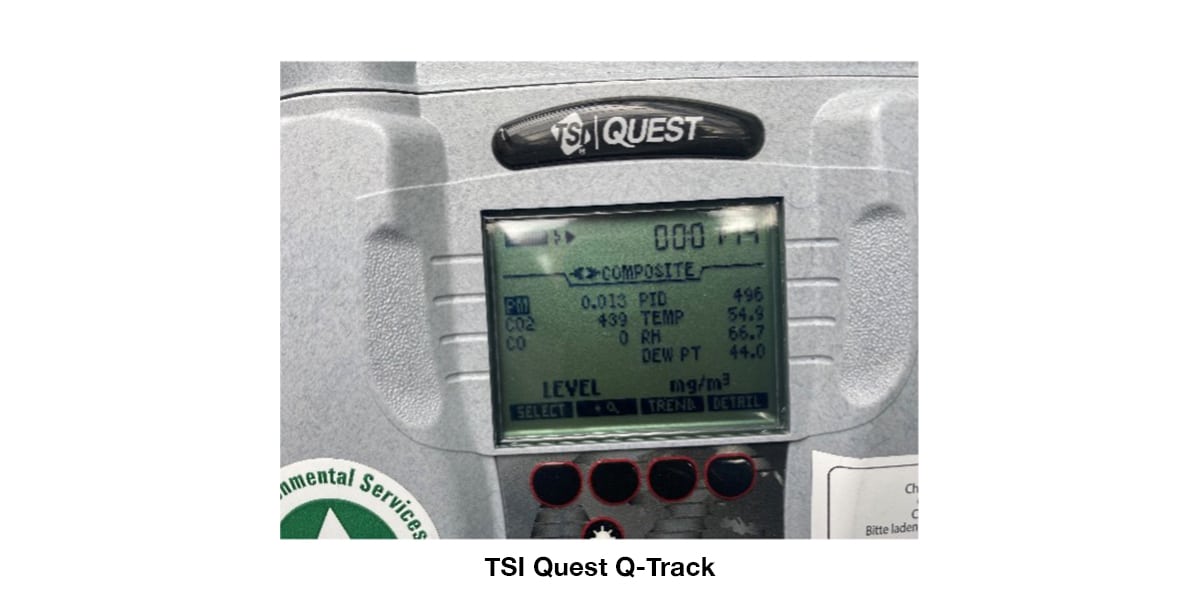

TSI Quest Q-Track

TSI’s Q-Track equipment monitors indoor air quality, measuring C02, CO, temperature, relative humidity, and other parameters of air quality and ventilation defined by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE).

The Q-Track equipment enables Omega to conduct thorough industrial hygiene surveys and IAQ assessments and identify the type, concentration and source of potentially harmful substances.

Infrared Cameras

Omega utilizes infrared cameras to detect thermal differentiation in walls, flooring, and other building materials. During assessments infrared cameras can detect and pinpoint moisture intrusion in building materials and take accurate temperature readings. Thermal imaging cameras can be used to detect hidden patches of moisture before water damage spreads and assists with the extend of moisture damage and finding suspect mold growth in building materials.

Moisture Meter

Often used in tandem with infrared cameras, moisture meters use prongs to measure the dampness of building materials such as drywall and wood structural studs. An elevated moisture reading helps to detect water damage and can aid in targeted remediation of impacted building materials to prevent the growth of mold and mildew.

Bio-Pump

The Zefon Bio-Pump supports indoor air quality assessments and remediation efforts. The pump samples indoor air with a flow rate of 15 liters/minute, providing our team with a precise and accurate measurement of airborne aerosols, such as mold spores, pollen, skin cells, insect parts, particulate and other contaminants.

Inside the equipment, a sample cassette with a spore trap captures potential airborne spores for lab analysis. The analysis of a spore trap cassette can identify the concentration and type of spores – from samples collected from inside and outside your building.

Once moisture and mold impacted building materials have been identified, Omega’s team can develop a plan for removing the impacted building materials, develop appropriate filtration methods to remove airborne spores and provide post remediation air sampling to determine if remediation is adequate and indoor air quality is safe for occupancy.

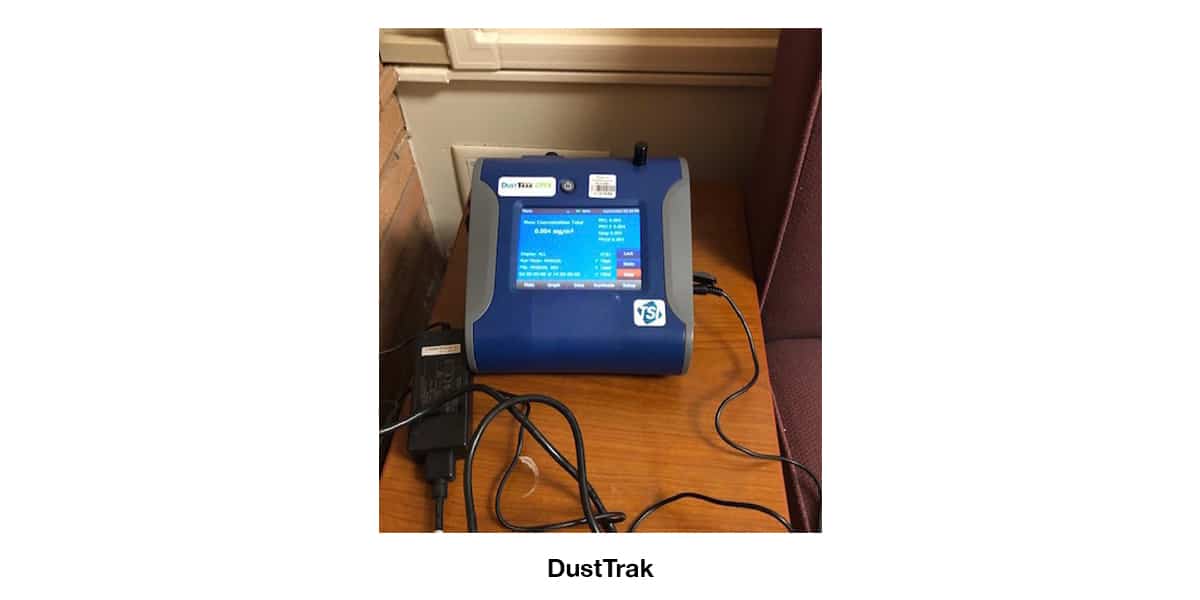

DustTrack™

The DustTrak™ aerosol monitor is a light-scattering photometer that provides real-time aerosol mass readings to detect and measure contaminants such as dust, smoke, fumes, and mists.

Used for the assessment of indoor air quality in workspaces, construction sites, and other areas and environmental sites. The DustTrak is a handheld monitor that offers a fast and accurate aerosol readings as part of industrial hygiene and IAQ assessments, and other environmental evaluations.

Phased Contrast Microscopes

Commonly used in asbestos assessments, our phase-contrast microscopes (PCMs) aid in the identification and counting of airborne fibers using a contrast-enhancing optical technique. These microscopes offer a more detailed view of airborne fibers that may pose a health and safety risk, such as asbestos. Typically, PCMs are used to determine airborne fiber concentration in work environments including offices, industrial settings, and during and after asbestos material remediation efforts.

Polarized Light Microscopy

Polarized light microscopes (PLMs) have a high level of sensitivity, making them useful in the identification of asbestos in bulk building materials as well as soil and rock. A bulk sample of a building material such as thermal system insulations, fireproofing, plasters, drywall, floor tiles, adhesives and many more materials are analyzed for asbestos content and the concentration of asbestos in the analyzed bulk material.

Transmission Electron Microscopy

For very small specimens, transmission electron microscopy (TEM) uses an accelerated electron beam to bring higher magnification and resolution to the task of identifying environmental samples. TEM is used for the identification of asbestos fibers in air and bulk building materials. TEM is capable of analyzing samples at a very high magnification, which enables the analyst to identify the type of asbestos fibers (chrysotile, amosite, actinolite, crocidolite, tremolite and anthophyllite) by their physical features.

VelociCalc® Air Meters

Air velocity meters measure the temperature and flow rate of air, along with the humidity level, dew point, and wet bulb temperature calculations in some cases. Used for IAQ assessments, ventilation system checks including fume hoods, paint spray booths and general office building ventilation. The air velocity meters measure the speed and/or volume of air movement of various types of ventilation systems and other environmental assessment to accurately – and quickly – determine if air flow is adequate for supplying or removing air from an area.

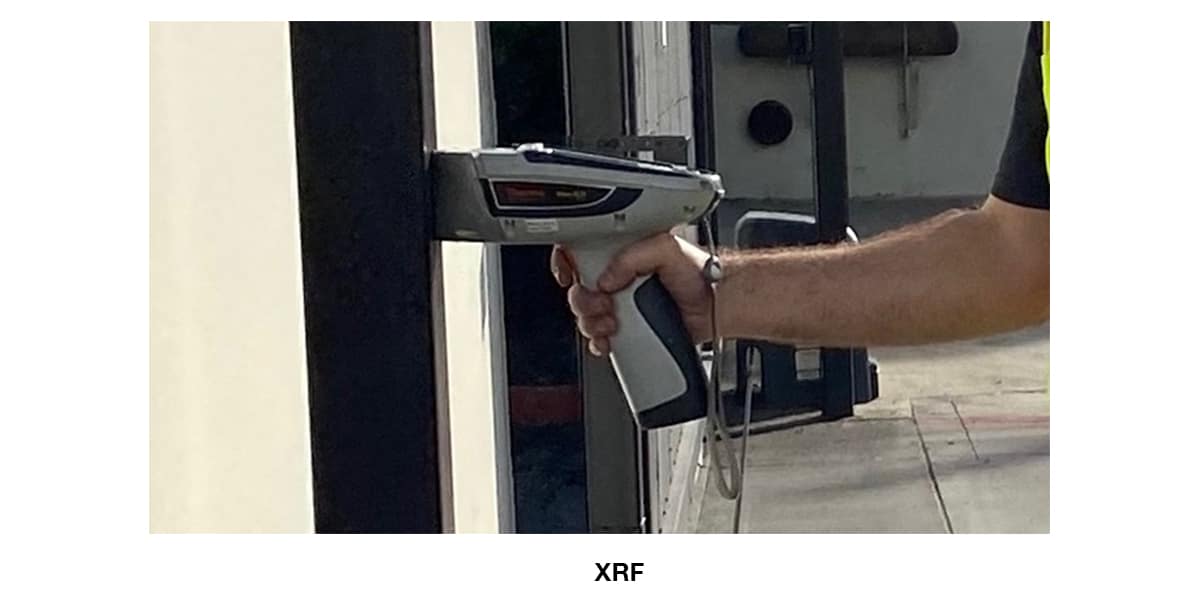

XRF – Xray Fluorescence Analyzers

XRF analyzers are the industry standard in assessments for lead-based paint. The handheld tool works by aiming an X-ray beam at the paint’s surface. The equipment then emits a second, fluorescent X-ray that is processed by the analyzer, providing a result within seconds. The XRF analyzers are an efficient tool for the detection of lead concentrations in paints and surface coatings. Knowing the lead concentration in paints or surface coatings on different building components (window frames, structural metal beams, walls, doors and more) can prevent workers from harmful exposure to airborne lead dust during construction and demolition activities.